No products in the cart.

New Laboratory Equipment, Fermentation

Winpact: Optimizing Your Fermentation Process

In the biotechnology and pharmaceutical industries, fermentation plays a key role in producing a wide array of products, from antibiotics and enzymes to biofuels and therapeutic proteins. As technology advances, so does the need for efficient and customizable fermentation solutions. This is where Winpact by GMI comes into the picture. In this blog post, we will delve into the world of Winpact and explore how it can revolutionize your fermentation process.

Understanding Fermentation

Fermentation is a natural process that involves the metabolic conversion of organic compounds by microorganisms, such as bacteria, yeast, and fungi. It is widely used to produce various valuable products, including pharmaceuticals, biofuels, and industrial enzymes. During fermentation, microorganisms break down complex organic substrates into simpler compounds, generating energy and producing desired end products.

The Role of Winpact

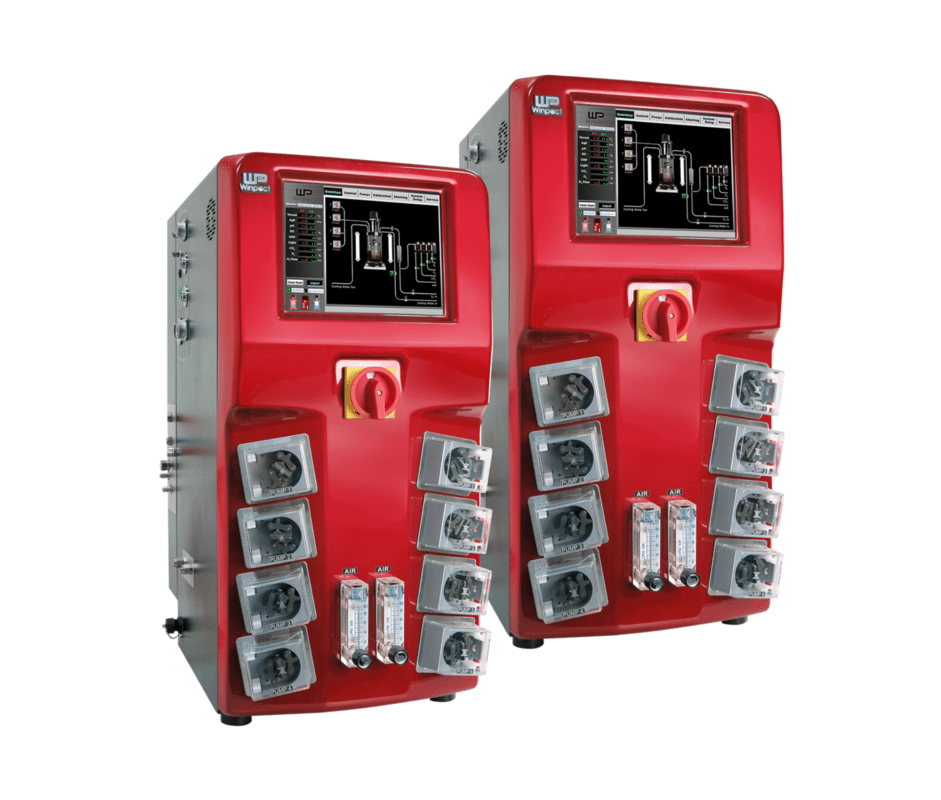

Winpact, offered by GMI, is a cutting-edge fermentation system designed to streamline and optimize the fermentation process. It provides a range of features that cater to the diverse needs of researchers and industries, ultimately enhancing productivity and product quality.

- Customizability

One of the standout features of Winpact is its flexibility and customizability. The system can be easily tailored to suit specific fermentation requirements, such as temperature, pH, dissolved oxygen, and agitation speed. This level of control empowers researchers to mimic precise conditions and achieve consistent results, making it an ideal tool for process optimization.

- User-Friendly Interface

Winpact boasts an intuitive and user-friendly interface that simplifies operation and monitoring. The system provides real-time data on key parameters, allowing users to make informed decisions and adjustments. This real-time insight is invaluable in maintaining optimal conditions and maximizing product yields.

- Scalability

Winpact covers various fermentation volumes, from small-scale laboratory experiments to large-scale industrial production. This scalability ensures a smooth transition from research and development to commercialization, eliminating the need for a complete equipment overhaul during the scale-up process.

- Data Management

Accurate data collection and management are crucial in the world of fermentation. Winpact’s data management system facilitates data logging, storage, and analysis, aiding process optimization and regulatory compliance. This feature is especially beneficial for industries with stringent quality control standards.

- Reliability and Reproducibility

Consistency is paramount in fermentation. Winpact’s advanced control algorithms and monitoring capabilities ensure reliable and reproducible results, reducing variability and minimizing experimental deviations. This level of reliability is essential for achieving consistent product quality and meeting regulatory requirements.

Conclusion

Optimizing the fermentation process in the dynamic landscape of biotechnology and pharmaceuticals is a constant pursuit. With Winpact from GMI, this pursuit becomes achievable but also efficient and customizable. By offering features such as a user-friendly interface, scalability, data management, and reliability, Winpact empowers researchers and industries to take their fermentation processes to new heights.

Whether you are working on groundbreaking research or seeking to enhance your industrial production, Winpact is poised to be a game-changer in your fermentation journey. To learn more about how Winpact can benefit your specific needs, contact GMI and discover the future of fermentation optimization.