No products in the cart.

New Laboratory Equipment

Why Lab Design is Critical to the Safety of Personnel

Safeguarding personnel is the number one priority in any laboratory environment. Proper lab design is critical to delivering on this and should both minimize the risk of accidents and support productivity. Key factors to consider are the type of work the lab will be used for, how many operatives will be sharing the workspace, and how much space is required. Importantly, the appropriate positioning of large, free-standing items of equipment such as biological safety cabinets (BSCs), CO2 incubators, and ultralow temperature (ULT) freezers helps prevent collisions or potentially harmful spills. This article shares some suggestions for lab design and includes insights from Matthew Decker, AIA, Architect, Lab Designer, and Group Lead at CRB.

Setting up the lab

A primary consideration when setting up a lab is avoiding overcrowding and minimizing foot traffic. Benches should be positioned to enable easy access to workspaces and may often incorporate dedicated zones for shared resources to prevent operatives from having to maneuver past one another as they go about their work. Where a particular activity is deemed high-risk, it can be sensible to implement a one-way system; this approach has been more widely adopted in recent times to help limit the spread of COVID-19.

The lab should also be easy to clean. Areas beneath benches should be readily accessible, and adequate storage space should be provided such that boxes of consumables are not piled up where they could gather dust or present a trip hazard. Walls, floors, and ceilings should be impermeable to liquids, including the broad array of chemicals and disinfectants routinely used in a laboratory environment, and benchtops should likewise be resistant to these solutions to avoid compromising the work surface.

Other factors to bear in mind include the provision of adequate lighting that does not cause unwanted reflection or glare; the inclusion of small windows in any doors leading into and out of the lab to help avert collisions; the availability of suitable containment (which may require ventilation) for hazardous reagents such as solvents; and access to a backup generator or surge suppressor to protect essential electrical equipment from power losses or voltage spikes. Additionally, large, free-standing items of equipment require careful siting to prevent them from becoming an obstruction that could lead to accidental spillage.

“Personnel safety is supported through good lab design when the design team has ample opportunity to produce and review the design with the people who will be using the lab space,” says Decker. “Such interaction is critical to educate both parties and build confidence in a solution that is both safe and functional. This conversation is easy to facilitate around day-to-day utilization of standard large lab equipment such as exposure control devices or temperature control chambers. Once the flow of information has been established, the team can engage in more complex aspects of the lab and its safety by design.”

Positioning large equipment

Large, free-standing equipment items such as BSCs, CO2 incubators, and ULT freezers are typically used by multiple operatives throughout the working day. For this reason, it is vital that they be positioned away from areas of heavy foot traffic and that they allow easy access to minimize the risk of spills. The lab design process should also address any equipment-specific requirements such as the provision of exhausting or plumbing for BSCs, availability of CO2 and N2 for microbiological incubators, and access to a dedicated power supply for ULT freezers.

Biological Safety Cabinets

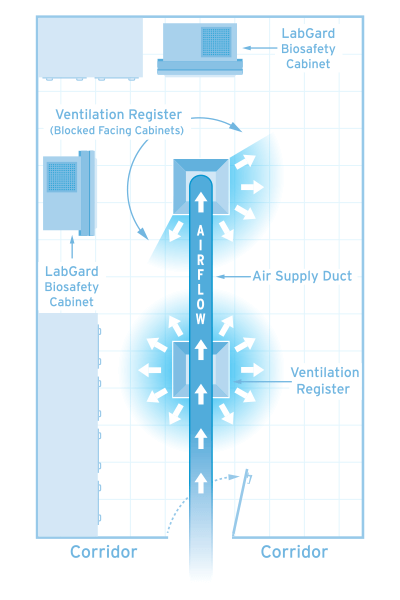

BSCs are primarily found in laboratories with a biosafety level (BSL) of 2 or above. To function effectively, they should be located away from personnel traffic, doors, fans, ventilation systems, fume hoods, and any other air-handling device with the potential to disrupt their airflow. Where possible, it is recommended that BSCs be located at the wall furthest from and facing the entry door; otherwise, the sidewall perpendicular to the hinge side of the door represents the next best option.

Clearances are a vital consideration when positioning a BSC. According to NSF/ANSI 49 – 2019 informative Annex 1, minimum clearances should include 6 inches (150 mm) from adjacent walls or columns, 6 inches (150 mm) between two BSCs, and 40 inches (1020 mm) of open space in front of the BSC. NSF/ANSI 49 – 2019 also provides comprehensive details of exhaust, electrical, and service line requirements. As additional equipment is introduced into the lab, positioning companion items such as cell counters and water baths near to BSCs helps streamline the workflow and reduce the chance of spills.

ULT Freezers

ULT freezers are used for high-capacity storage of sample material such as cell lysates or tissue homogenates, which they maintain at or below -80oC. They should be sited away from heat sources, including direct sunlight, that can compromise function, and should be provided with adequate clearance for door opening. “Large critical storage units such as ULT freezers need sufficient spacing for airflow but also for maintenance of compressors,” said Decker.

CO2 Incubators

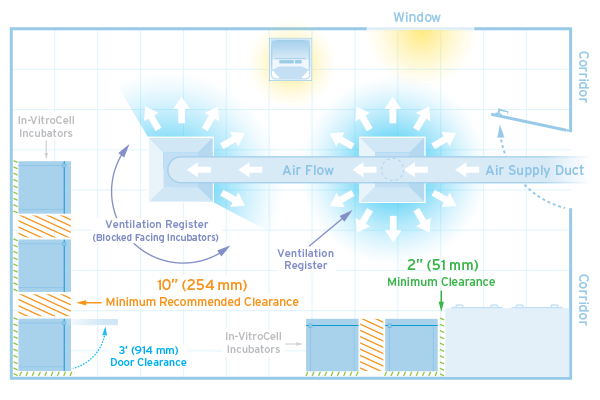

CO2 incubators provide a regulated environment for cells grown in culture. Lab design should ensure they are supplied with CO2 and N2 (if required) and are installed away from direct heat and rapidly moving air currents. Clearances are essential to the safe functioning of CO2 incubators. They should include a minimum of 2 inches (51mm) between the rear and sides of the incubator and any non-heat generating surface. A minimum of 10 inches (254 mm) between incubators to prevent high-temperature sterilization cycles from interfering with the normal operation of an adjacent unit. Other essential safety considerations include leaving at least 3 ft (914mm) in front of the incubator to allow clearance to open the door; allowing easy access to the power cord for connection and disconnection, and ensuring the control center electronics remain accessible for maintenance and service.

The GMI team is happy to help you set up a safe lab, schedule a free consultation now.