No products in the cart.

HPLC, New Laboratory Equipment

Troubleshooting Guide for HPLC Pumps: Tips and Tricks

High-Performance Liquid Chromatography (HPLC) pumps are critical components of HPLC systems, responsible for delivering precise and consistent flow rates of mobile phase solvents. However, like any complex instrument, HPLC pumps can experience issues that may affect their performance. This troubleshooting guide will discuss common problems encountered with HPLC pumps and provide tips on resolving them. Remember, if you need further assistance, our dedicated service team at GMI is here to help.

-

Irregular Flow Rates

Symptoms: The HPLC pump exhibits erratic or fluctuating flow rates, leading to inconsistent chromatographic results.

Possible Causes and Solutions:

- Air Bubbles: Check for air bubbles in the solvent lines or pump head. Purge the system and ensure proper solvent degassing.

- Blocked or Clogged Lines: Inspect the solvent lines and inlet filters and check valves for blockages. Clean or replace components as needed.

- Pump Calibration: Verify the pump calibration and adjust the flow rate settings if necessary. Recalibrate the pump according to manufacturer guidelines.

-

Pressure Fluctuations

Symptoms: The HPLC system experiences pressure fluctuations or spikes during operation, affecting column performance and peak shapes.

Possible Causes and Solutions:

- Column Issues: Check the HPLC column for clogging, degradation, or improper packing. If necessary, replace or repack the column.

- Leakages: Inspect the system for leaks at fittings, tubing connections, and seals. Tighten connections or replace damaged components.

- Pump Seal Wear: Check the pump seals for wear or damage. Replace seals regularly as part of routine maintenance.

-

Prime/Inject Errors

Symptoms: The HPLC pump displays prime or inject errors, indicating issues with solvent delivery or sample injection.

Possible Causes and Solutions:

- Sample Overload: Ensure that the sample volume and concentration are within the recommended limits to prevent system overload.

- Injector Maintenance: Clean and inspect the autosampler injector for debris or wear. Replace injector parts if necessary.

- Solvent Compatibility: Confirm that the mobile phase solvents are compatible with the system components and column chemistry to avoid solvent-induced errors.

-

System Alarms or Error Codes

Symptoms: The HPLC pump triggers alarms or displays error codes, indicating system malfunctions or failures.

Possible Causes and Solutions:

- Power Supply Issues: Check the power supply and connections for stability and proper voltage. Address any electrical issues promptly.

- Software Updates: Ensure the HPLC system software is updated with the latest patches and firmware upgrades.

- Instrument Diagnostics: Run diagnostic tests provided by the manufacturer to identify and troubleshoot specific system errors.

How GMI Service Team Can Help

If you encounter persistent issues with your HPLC pump that cannot be resolved through basic troubleshooting, don’t hesitate to contact our GMI service team. Our experienced technicians and engineers are well-versed in HPLC systems and can provide expert assistance, including onsite maintenance, repairs, and instrument validation. With GMI’s support, you can ensure the optimal performance and reliability of your HPLC instrumentation.

In conclusion, troubleshooting HPLC pumps requires a systematic approach to identify and address underlying issues. By following the tips outlined in this guide and leveraging the expertise of our service team at GMI when needed, you can overcome challenges and achieve accurate and reliable chromatographic results in your analytical work.

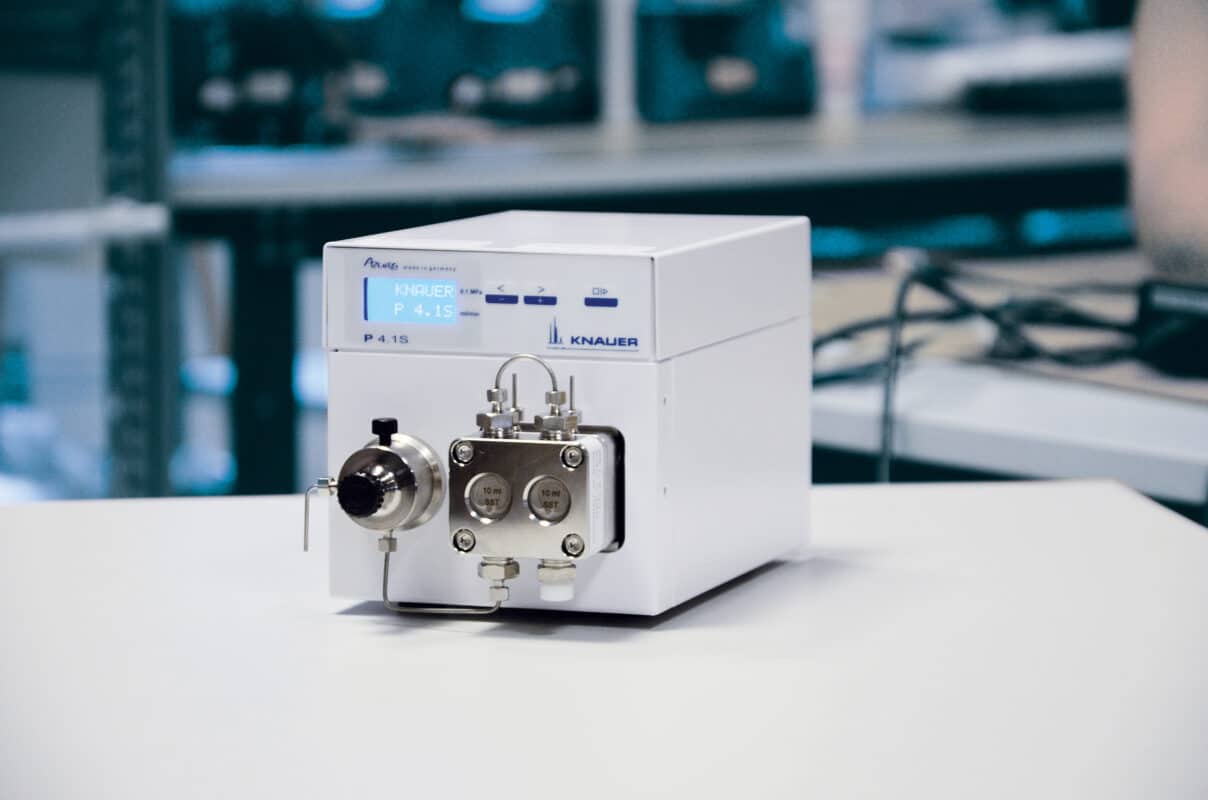

GMI repair & service shop knauer pumps