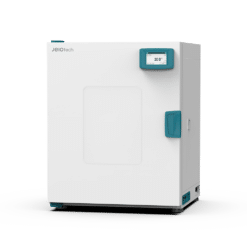

Memmert’s Cooled Storage Incubator (IPPeco) is the most energy-efficient and powerful cooled incubator of its kind due to state-of-the-art Peltier technology. Heat-up, cool down and recovery times are much shorter than comparable incubators. The Peltier-cooled incubator from Memmert saves on operating costs, ensures sample uniformity and makes work more efficient. Common applications include microbiology studies, bacterial count determination, shelf-life testing for dairy products and beer stability testing. Highly efficient Peltier cooled incubators operate with very low noise, almost no vibration, and low energy consumption. In addition, Memmert Peltier cooled incubators are precise with tight controls.

Memmert Peltier Cooled Incubators

Not sure which configuration is right for your application? Schedule a free consultation with our technical consultants today!

Schedule a consultationProduct Description

Sealed Interior Chamber

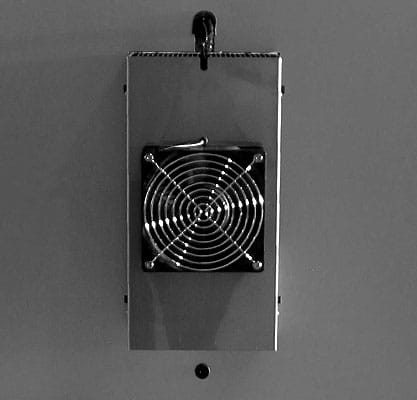

No Compressor

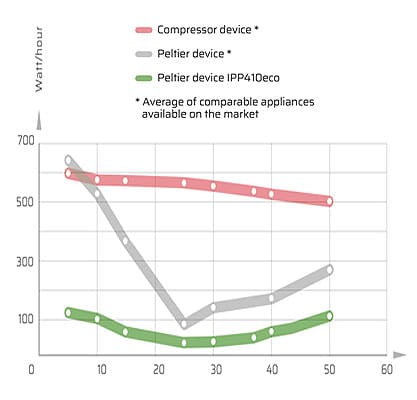

Save Energy

Peltier technology delivers a greater temperature range with precise control while saving on energy.

Temperature Recovery

Maximize finely-tuned temperature adjustments and recovery times with the impressive performance provided by Peltier technology.

Technical Specifications

| Model sizes/Description | 30 | 55 | 110 | 260 | 410 | 750 | 1060 | 1400 | 2200 | |

|

Stainless steel interior

|

Volume approx. l | 32 | 53 | 108 | 256 | 384 | 749 | 1060 | 1360 | 2140 |

| Width (A) mm | 400 | 560 | 640 | 1040 | 1250 | 1972 | ||||

| Height (B) mm | 320 | 400 | 480 | 800 | 1200 | 1450 | ||||

| Depth (less 10 mm (sizes 30 and55), less 32 mm (sizes 110 to2200) for fan – Peltier)(C) mm | 250 | 330 | 400 | 500 | 600 | 850 | 750 | |||

| Max. number of grids/shelves number | 3 | 4 | 5 | 9 | 14 | 28 | 42 | |||

| Max. loading per grid/shelf kg | 20 | 30 | 20 | 30 | ||||||

| Max. loading of chamber kg | 60 | 80 | 150 | 200 | 250 | 330 | ||||

| Max. loading per slide-in drip tray kg | 1,5 | 3 | 4 | 8 | – | |||||

| Max. loading per bottom drip tray kg | 1,5 | 3 | 4 | 8 | – | |||||

|

Textured stainless steel exterior

|

Width (D) mm | 585 | 745 | 824 | 1224 | 1435 | 2157 | |||

| Height (sizes 410, 750, 1060 with castors) (E) mm | 704 | 784 | 864 | 1183 | 1720 | 1913 | ||||

| Depth (without door handle, depth of handle +56 mm) (F) mm | 434 | 514 | 555 | 655 | 755 | 1005 | 905 | |||

|

Standard equipment

|

Stainless steel grids, electropolished number | 1 | 2 | 4 | 6 | |||||

| Standard works calibration certificate (measuring point chamber center) °C | 10 to 37 | 25 to 40 | ||||||||

|

Temperature

|

Working temperature range without light °C | 0 (at least 20 below ambient temperature) to +70 | 15 (at least 10below ambienttemperature) to +60 | |||||||

| Working temperature range with light °C | – | 10 to 40 | – | |||||||

| Setting temperature range °C | 0 to 70 | 15 to 60 | ||||||||

| Setting accuracy °C | 0.1 | |||||||||

|

Further data

|

Electrical load at 230 V, 50/60 Hz approx. W | 140 | 275 | 320 | 600 | 1200 | 1800 | |||

| Electrical load at 115 V, 50/60 Hz approx. W | 140 | 275 | 320 | 600 | 1200 | – | ||||

| Peltier elements in the rear number | 1 | 2 | 4 | 6 | ||||||

|

Packing data

|

Net weight approx. kg | 40 | 52 | 78 | 114 | 157 | 230 | 255 | 450 | 493 |

| Gross weight (packed in carton) approx. kg | 56 | 71 | 103 | 165 | 210 | 301 | 419 | 639 | 730 | |

| Width approx. mm | 660 | 730 | 830 | 930 | 1330 | 1370 | 1560 | 2300 | ||

| Height approx. mm | 890 | 950 | 1050 | 1380 | 1930 | 1910 | 1970 | 2200 | ||

| Depth approx. mm | 650 | 670 | 800 | 930 | 1050 | 1300 | 1190 | |||

|

Order No. Peltier-Cooled IncubatorsIPP = Peltier-Cooled Incubatorsplus = Model with TwinDISPLAY (IPP1400eco/ IPP1400ecoplus and IPP2200eco/ IPP2200ecoplus (available from Q2 2021)

|

IPP30 | IPP55 | IPP110eco | IPP260eco | IPP410eco | IPP750eco | IPP1060eco | IPP1400eco | IPP2200eco | |

| IPP30plus | IPP55plus | IPP110ecoplus | IPP260ecoplus | IPP410ecoplus | IPP750ecoplus | IPP1060ecoplus | IPP1400ecoplus | IPP2200ecoplus | ||

Memmert products are equipped with AtmoCONTROL technology that has programming functions depending on which display you select:

![]()

This simple and intuitive interface allows you to seamlessly control all aspects of your equipment. Perfect for standard applications but still offers reliability and precision consistent with any Memmert equipment.

![]()

The more complex twin display allows users to control every aspect of equipment functionality. Even complex processes such as multiple overtemperature protection, visual and acoustic alarm as well as automated alarm messages can be programmed quickly and easily.

| Weight | 1600 oz |

|---|---|

| Dimensions | 40 × 48 × 48 in |

| Model | IPP110eco, IPP110eco PLUS, IPP260eco, IPP260eco PLUS, IPP30, IPP30 PLUS, IPP410eco, IPP410eco PLUS, IPP55, IPP55 PLUS, IPP750eco, IPP750eco PLUS |