No products in the cart.

New Laboratory Equipment, Fermentation

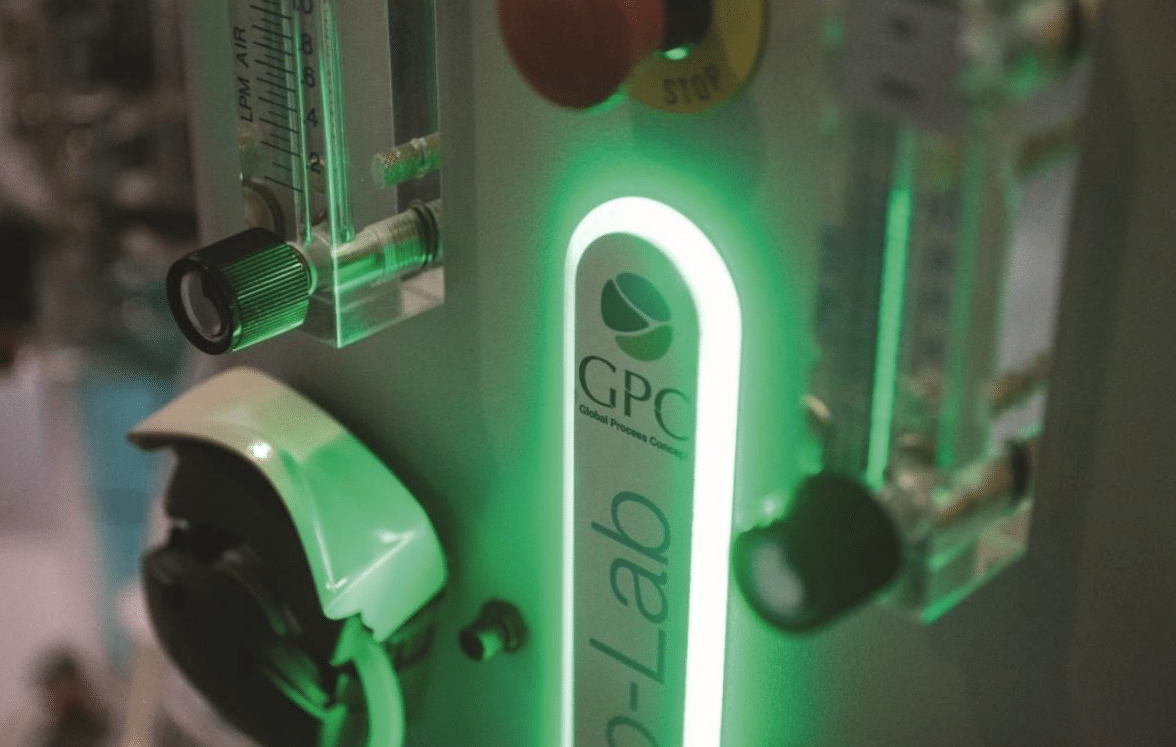

Making GMP Compliance Simpler with GPC Bio in Fermentation

Introduction

Good Manufacturing Practices (GMP) are the foundation of quality assurance in the pharmaceutical and biotechnology industries. Ensuring compliance with GMP regulations is essential for the safety, efficacy, and consistency of products manufactured in these sectors. A critical aspect of GMP compliance is maintaining strict control over fermentation processes. GPC Bio, available through GMI, offers innovative solutions that simplify GMP compliance in fermentation. In this blog post, we’ll explore the significance of GMP compliance in fermentation and how GPC Bio products can make this complex task more manageable.

gpc bio from gmiUnderstanding the Importance of GMP in Fermentation

Fermentation processes play a central role in producing biopharmaceuticals, vaccines, antibiotics, and other critical products. Ensuring GMP compliance during fermentation is vital for the following reasons:

- Product Quality: GMP-compliant fermentation processes help maintain the quality, purity, and consistency of the final product, reducing the risk of contamination or variability.

- Patient Safety: Compliance with GMP standards ensures that the medications and therapies produced are safe for patient consumption or use.

- Regulatory Approval: Regulatory authorities such as the FDA and EMA require GMP compliance for product approval and market authorization.

- Data Integrity: Proper documentation and adherence to GMP principles enhance data integrity, allowing for accurate process monitoring and traceability.

Simplifying GMP Compliance with GPC Bio

GPC Bio, available through GMI, is a leading provider of fermentation solutions designed to streamline GMP compliance. Here’s how GPC Bio products can simplify the GMP process in fermentation:

- Single-Use Bioreactors: GPC Bio offers a range of single-use bioreactors that eliminate the need for cleaning and sterilization validation, reducing the risk of cross-contamination. These bioreactors are designed for easy installation and scalability, allowing for efficient fermentation at different production scales.

- Advanced Process Control: GPC Bio’s fermentation solutions have advanced process control systems, enabling real-time monitoring and precise control over critical process parameters. This ensures consistent product quality and reproducibility.

- Data Management: GPC Bio provides user-friendly data management and analysis tools that simplify data capture, analysis, and reporting, ensuring compliance with GMP documentation requirements.

- Customized Solutions: GPC Bio understands that each fermentation process is unique. They offer tailored solutions and expert support to address specific GMP compliance challenges, making it easier to meet regulatory requirements.

- Quality Assurance: GPC Bio’s commitment to quality assurance ensures that its products meet the highest industry standards, providing peace of mind to manufacturers aiming for GMP compliance.

Conclusion

GMP compliance in fermentation is non-negotiable for the pharmaceutical and biotechnology industries. GPC Bio, available through GMI, offers a range of cutting-edge solutions that simplify the challenges associated with GMP compliance. From single-use bioreactors to advanced process control and data management tools, GPC Bio’s offerings are designed to enhance the quality, safety, and efficiency of fermentation processes. By choosing GPC Bio products, you can simplify your journey to GMP compliance and ensure the success of your pharmaceutical and biotech endeavors. Explore GMI’s inventory of GPC Bio products today and take a significant step toward achieving GMP excellence in fermentation.

gpc bio from gmi