No products in the cart.

Laboratory Equipment, Fermentation

Benchtop Fermentation: Exploring Pros, Cons, and Boundless Potential

Introduction

In biotechnology and life sciences, fermentation is a cornerstone for producing a wide range of valuable products. Traditionally associated with large-scale industrial operations, fermentation has evolved to accommodate smaller-scale applications through benchtop systems. In this insightful blog, we delve into the world of benchtop fermentation, examining its advantages, limitations, and the promising potential it brings to the laboratory landscape in collaboration with GMI.

The Power of Benchtop Fermentation

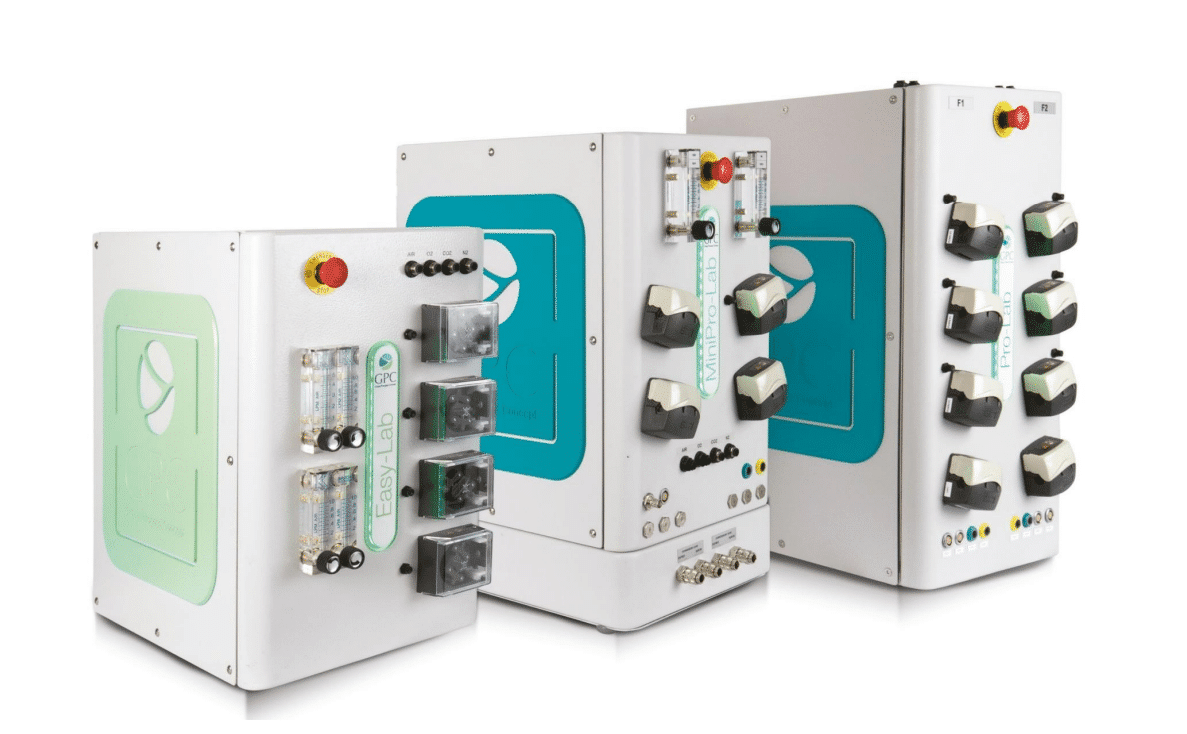

Fermentation, the process of using microorganisms to convert substrates into valuable products, has seen a paradigm shift with the advent of benchtop systems. These compact, versatile setups allow researchers to explore fermentation’s intricacies without requiring extensive resources or dedicated facilities. GMI, a key player in providing innovative laboratory solutions, recognizes the significance of benchtop fermentation and its role in democratizing scientific exploration.

Pros of Benchtop Fermentation

- Cost-Effectiveness: Benchtop fermenters significantly reduce the investment required compared to industrial-scale systems. This accessibility empowers smaller research laboratories and startups to engage in fermentation-based projects.

- Flexibility and Customization: Benchtop systems are adaptable and can be configured to suit specific experimental requirements. Researchers can fine-tune parameters such as pH, temperature, and agitation, enabling precise control over fermentation conditions.

- Real-Time Monitoring: Many benchtop fermenters have advanced sensors and monitoring systems. This allows researchers to track parameters and make adjustments in real-time, enhancing process optimization.

- Reduced Footprint: Space constraints are less of an issue with benchtop systems, making them ideal for laboratories with limited space. Their compact design also simplifies installation and maintenance.

- High Throughput: Benchtop fermenters can be operated in parallel, enabling researchers to conduct multiple experiments simultaneously. This accelerates research and increases data output.

Cons and Considerations

- Scale Limitations: While benchtop fermenters are excellent for research and development, they might not be suitable for large-scale production due to their limited capacity.

- Process Transfer Challenges: Scaling up from benchtop to industrial production might require adjustments to account for differences in mixing, oxygen transfer, and other parameters.

- Resource Limitations: Some processes, particularly those requiring significant biomass or long fermentation times, might strain the capabilities of benchtop systems.

Potential Applications

- Strain Development: Benchtop fermentation is pivotal for optimizing microbial strains for improved product yield or characteristics.

- Biopharmaceuticals: Benchtop systems facilitate the production of therapeutic proteins, antibodies, and other biopharmaceuticals in research and small-scale settings.

- Biofuel Research: Benchtop fermentation plays a role in developing biofuels from renewable sources, contributing to sustainable energy solutions.

- Environmental Monitoring: Benchtop fermenters aid in studying environmental factors affecting microbial growth and metabolite production.

Conclusion

Benchtop fermentation has transcended the barriers of space and budget, bringing fermentation experiments within reach of a broader scientific community. The synergy between GMI and benchtop fermentation technologies has opened doors to innovative research across domains. While limitations exist, the potential for discovery and advancement in biotechnology, pharmaceuticals, and beyond is boundless. As benchtop systems continue to evolve and adapt, they promise to reshape the landscape of scientific exploration, empowering researchers to unlock the secrets of microbial processes and contribute to a brighter future.

Schedule a free consultation to learn more