Nuaire 200 L CO2 Incubator 230V

Factory Clearance Inventory fluctuates quickly, please call GMI to inquire about inventory availability.

Not sure which configuration is right for your application? Schedule a free consultation with our technical consultants today!

Schedule a consultation Have One To Sell?Product Description

200-LITER CAPACITY | TEMP, CO2, HUMIDITY, & O2 CONTROL | HEPA FILTRATION | STERILIZATION CYCLES

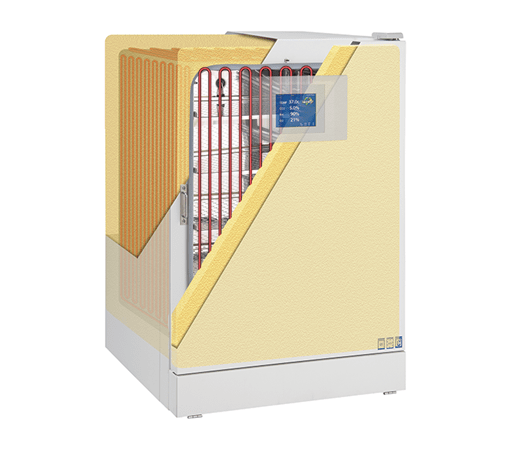

This line of CO2 incubators offers touch panel control and monitoring of temperature, CO2, relative humidity, and oxygen levels to meet the demands of a broad range of cell culture applications. Beyond using an infrared sensor for precise control of CO2 and separately adjustable chamber, door and perimeter heaters to balance internal temperature, this family can create hypoxic conditions by injecting N2 and directly control humidity to set point by routing air through an evaporator tank. The air pump outside the 200L growth chamber also constantly draws air through a HEPA filter and cycles it back to create ISO Class 5 quality air at positive pressure and minimize contamination. Scientists can choose between a 95C humidified or 145C dry decontamination depending on their laboratory’s procedures. A touch screen makes it easy to enter set points as well as to view or download historical performance. This moderately sized incubator can be stacked to efficiently use the valuable space in your laboratory.

Quick Specs

| AIR CLEANLINESS (ISO 14644) | ISO-Class-5 |

|---|---|

| CO2 ACCURACY | ± 0.1% |

| CO2 RECOVERY | Up to 5% ± 0.2% / -0.5 in 5 minutes Average |

| CONTROL SYSTEM | NuTouch |

| TEMPERATURE ACCURACY °C | ± 0.1% |

| TEMPERATURE CONTROL | Direct Heat |

| TEMPERATURE RECOVERY | 0.12°C/min. on Average |

| TEMPERATURE UNIFORMITY °C | ± 0.35°C @ 37°C |

Features

- Cold Rolled Steel with Powder Coated Finish Exterior

- Polished, 16 Gauge Type 304L Stainless-Steel Chamber

- Set of 4 Stainless Steel Shelves

- Inner Glass Door

- Separately Adjustable Perimeter & Door Heaters

- Infrared CO2 Sensor

- Dual Temperature Sensors

- Air Pump External to Chamber

- HEPA Filter External to Chamber

- Multilingual Touch Screen

- USB Port for Data Download

- RH Sensor and Evaporator Tank

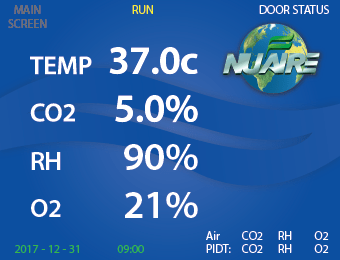

THE MODERN USER EXPERIENCE YOU EXPECT.

NUTOUCH CONTROL SYSTEM

The NuTouch control system provides you with the user experience you have come to expect from any piece of modern equipment. Change set points, view chamber history, start a decontamination cycle, or perform a calibration procedure from this simple interface. All NuAire CO2 incubators standardize on the NuTouch control system, meaning that once users learn to navigate one incubator they can move seamlessly to any other in the lab.

THE WARM EMBRACE OF DIRECT HEAT TECHNOLOGY.

DIRECTLY HEATED CHAMBER

The direct heat incubator uses heating elements placed around the chamber, in the door perimeter, and in the door itself to provide balanced temperature within a steel, insulated chamber environment. Door and perimeter heaters can be adjusted independently to ensure uniformity even when the incubator is installed in more demanding ambient temperatures.

CONVENIENT CONTAMINATION CONTROL.

145C HEATED DECONTAMINATION

The direct heat technology enables the use of a 145C decontamination cycle that can be conveniently run overnight in just 8 hours without removing the CO2, temperature, or O2 sensors. The NuTouch control system steps the user through the process with on screen instructions and displays progress throughout each phase of the complete cycle.

CELL CULTURES DESERVE THEIR OWN CLEAN ROOM.

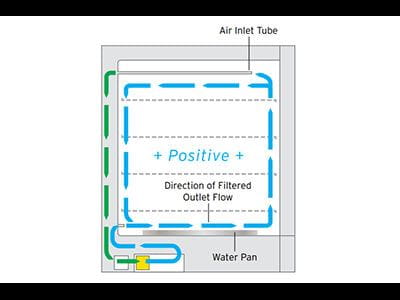

CONSTANT HEPA AIR FILTRATION

Continual HEPA filtration of chamber air complements periodic high heat decontamination to provide Constant Contamination Control. InVitrocell’s design constantly takes a sample of air from the chamber, routes it through a HEPA filter in a compartment outside that inner chamber, and ultimately returns it to create an ISO Class 5 level of clean air in the interior as well as a slight positive pressure. Inside the InVitrocell, your cell cultures are protected by a multi-tiered defense against contamination.

Specifications

| Est. Shipping Width Inches (mm) | 31 (787) |

| Est. Shipping Height Inches (mm) | 51(1219) |

| Est. Shipping Depth Inches (mm) | 31 (787) |

| Access Port Location | Right Side |

| Air Cleanliness (ISO 14644) | ISO-Class-5 |

| Chamber Air Circulation Method | Air Pump |

| Chamber Air Filter | 99.97% Efficiency @ ≥ 0.3 Micron Capsule Filter Located in Sensor Bay |

| Chamber Heater(s) Location | Walls, Top and Bottom of Chamber |

| Chamber Jacket Technology | Air Jacket via One or Two Axial Fans Drawing Air into Shell |

| CO2 Accuracy | ± 0.1% |

| CO2 Control Logic | Fixed Algorithm/Manual, Environmental Adaptable |

| CO2 Display Resolution | 0.1% |

| CO2 Range | 0.1 to 20%, 5% Default Set Point |

| CO2 Recovery | Up to 5% ± 0.2% / -0.5 in 5 minutes Average |

| CO2 Sensor Type | Infrared (NDIR) |

| Control System | NuTouch |

| Data Output Features | RS-485, USB, 4-20mA |

| Door and Perimeter Heater Control Logic | Base Duty Cycle set to chamber temperature Set-Point, Proportional 0-100% [manually adjustable |

| Electrical Configuration | 115V50Hz, 230V5060Hz |

| Exterior Depth Inches (mm) | 27.188 (691) |

| Exterior Door Seal | Magnetic Outer Door Gasket |

| Exterior Height Inches (mm) | 39.688 (1008) |

| Exterior Material | Cold Rolled 16 & 18 Gauge Steel, Finished in Powder Coated Polyurethane Finish |

| Exterior Width Inches (mm) | 26.750 (680) |

| Footprint Depth inches (mm) | 20.75 (527) |

| Footprint Width inches (mm) | 23.75 (603) |

| In-line Gas Filters | 99.97% Efficiency @ ≥ 0.3 Micron Disk Filters for Gas & Air Supplies, Disk Filter for CO2 Sensor |

| Segmented Doors | Optional Set of 6 Inner Doors, 2 Across by 3 Down |

| Inner Doors | One |

| Insulation | High Density Insulation with High “R” Rating |

| Interior Depth Inches (mm) | 20.053 (509) |

| Interior Door Seal | Silicone Rubber Gasket |

| Interior Height Inches (mm) | 28.500 (724) |

| Interior Material | Polished Type 304L 16 Gauge Stainless Steel |

| Interior Volume Cubic Feet (Liters) | 7.06 (200) |

| Interior Width Inches (mm) | 21.257 (540) |

| Net Weight lbs (kg) | 235 (106) |

| O2 Accuracy | ± 0.25% |

| O2 Control Logic | Fixed algorithm/ manual environmental adaptable |

| O2 Display Resolution | 0.1% |

| O2 Measuring Range | 0 – 25% |

| O2 Set Point Range | 0.5 – 21.0% (ambient) (21.0% Default) (2 – 21.0% when RH setpoint is above 90%) |

| O2 Recovery | 5.0 ± 0.5% twenty minutes on Average |

| O2 Sensor Type | Zirconia Ceramic |

| Power Cord Length Foot (Meter) | 8 (2.5) |

| Remote Alarm Terminals | Standard |

| RH Accuracy | +5% /- 3% |

| RH Control Method | Water Pan or Evaporator Box, Depending on Model |

| RH Control Logic | Fixed algorithm/ manual environmental adaptable |

| RH Control Range | Ambient dependent to 95% |

| RH Display Resolution | 0.1% |

| RH Evaporator Box Capacity | 3L |

| RH Recovery | 90% +5%/-3% within 25 minutes on average |

| RH Sensor Type | Precision capacitance bulk-polymer |

| RH Water Pan Capacity | 2L (Recommended Fill 1.5L) |

| Sample Port Location | Inner Glass Door |

| Shelf Capacity lbs (kg) | 25 lbs per Shelf / 125 lbs per Incubator |

| Shelf Depth Inches (mm) | 18 3/4 (476) |

| Shelf Material | Stainless Steel |

| Shelf Width Inches (mm) | 19 3/4 (502) |

| Shelves | 4 Shelves Supplied, 20 Shelves Maximum Capacity |

| Est. Shipping Weight lbs (kg) | Estimated 325 lbs (147 kgs) |

| Decontamination Cycle | True (False on NU-5800, NU-5800E) |

| Temperature Accuracy °C | ± 0.1% |

| Temperature Control | Direct Heat |

| Temperature Control Range | 5°C above ambient (to a 30°C max ambient) to 55°C |

| Temperature Display Resolution | 0.1°C |

| Temperature Recovery | 0.12°C/min. on Average |

| Temperature Sensor Type | Precision Integrated Circuit |

| Temperature Set-Point Range | 5°C to 55°C (37.0°C Default) |

| Temperature Uniformity °C | ± 0.35°C @ 37°C |

| Water Pan Depth | 1.5 (38) |

| Water Pan Length Inches (mm) | 12 (305) |

| Water Pan Width | 10 (254) |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.